Success Story

LASP

LASP, or the Laboratory for Atmospheric and Space Physics, at the University of Colorado Boulder (USA) is the only academic research institute in the world to have sent scientific instruments to every planet in our solar system, the sun, and a host of moons. Successfully building and launching over 150 CubeSats, for which NASA was the primary customer. LASP’s rich 75-year history is literally out of this world and its proud tradition of innovation keeps it at the cutting edge of science.

LASP Challenge

LASP used to build their own release mechanisms based on burn-wire technology, which required them to spend a lot of time, effort, and money to refurbish them. This led to their teams only performing minimal required testing due to the cost, hassle, and time required to reset their deployables. This significantly increased the risk of potential mission failure due to the mission-critical nature of these release mechanisms. With burn-based mechanisms, you can either test them or fly them due to their expendable nature.

Dcubed solution

Dcubed worked with the LASP teams to determine the best solutions for their missions, eventually ordering over a dozen nano pin pullers and nano release nuts. Since Dcubed’s shape memory alloy-based actuators allow for over 100 repeatable tests and reset within seconds, it allows LASP to follow a “test as you fly and fly as you test” approach without the extra time or cost investment, while simultaneously reducing their mission risk.

Dcubed impact

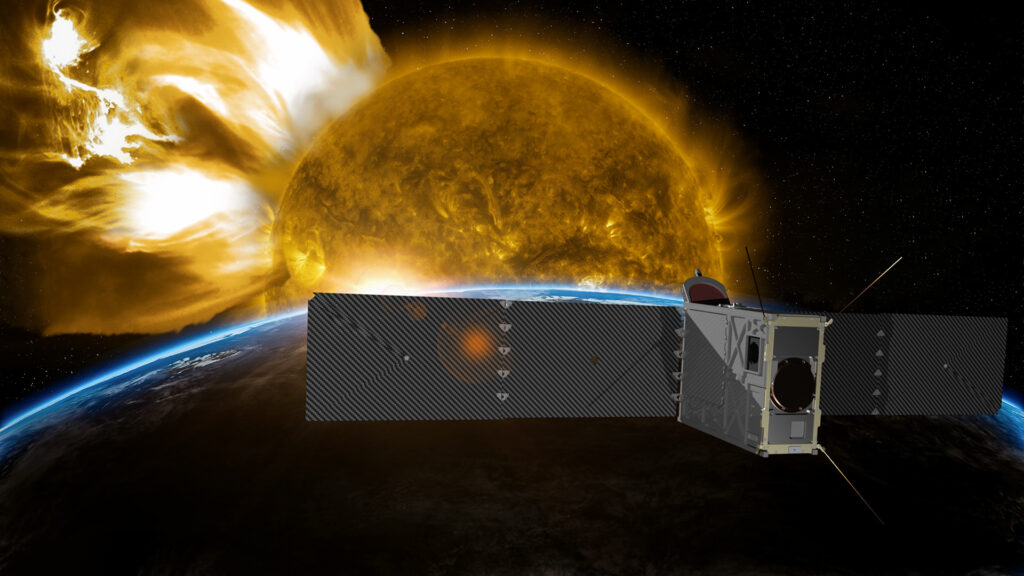

LASP is currently using Dcubed actuators for NASA’s DynaGlow and SunCet CubeSats to trigger a variety of onboard mechanisms like aperture doors and deployables from antennas to solar arrays. This allowed LASP’s teams to realize a 23% faster development cycle and seize an 11% risk reduction due to the ability to have continuous, effortless deployment testing.

By loading the video, you agree to YouTube's privacy policy.

Learn more