About the Quartus Engineering Test

Quartus Engineering is a recognized leader in high-precision aerospace testing, with a focus on high reliability. Its key expertise is in analysis & testing, custom metrology solutions, robotics & mechanisms, and precision optical systems. When it had a requirement to capture some actuator shock test data, the company reached out to Dcubed to request some test units. For Dcubed, this was a great opportunity to independently verify the shock performance of its uD3RN Micro Release Nut via a partner with the technical know-how and advanced measurement tools needed to thoroughly test the device.

The goal of the campaign was to evaluate the mechanical shock produced by the uD3RN during release events and determine its suitability for shock-sensitive missions and payloads. These include spacecraft carrying fragile optical systems, deployable structures, or precision instruments where shock-imposed vibrations can be a risk. A secondary aim was to assess the repeatability and consistency of the device across multiple triggers under identical conditions.

A successful test would also further support Dcubed’s reputation as a component partner that can reliably deliver on ultra-low shock requirements. This is particularly important in the context of the “Test as you fly, fly as you test” protocol, which is now mandatory for spacecraft owners that want to fly on SpaceX rideshare missions.

Testing Setup

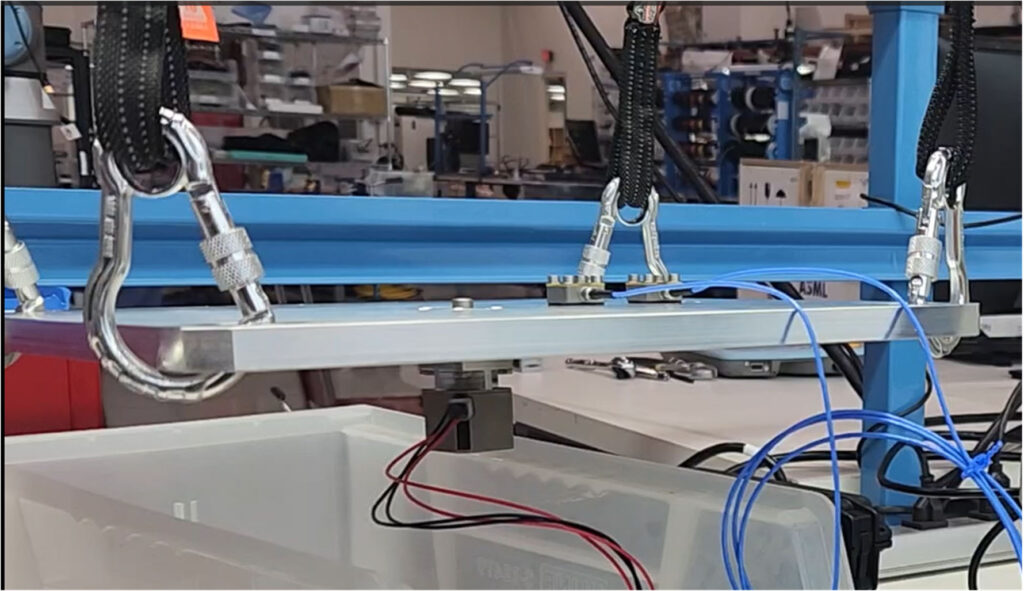

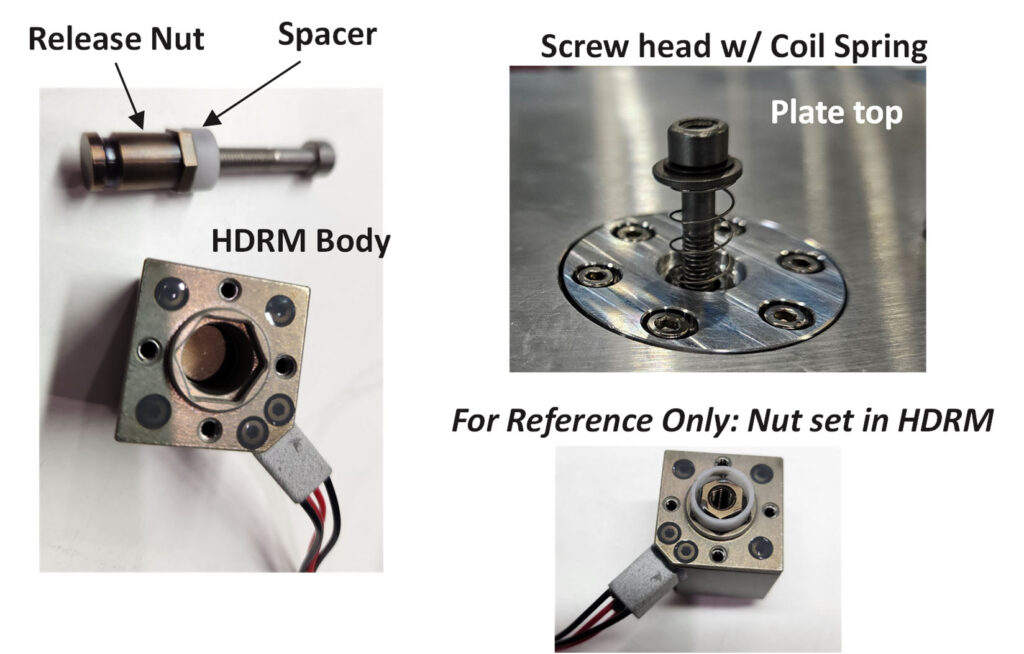

Quartus Engineering designed a custom test rig to simulate real-world launch and deployment scenarios. The setup incorporated representative masses and mounting structures to ensure that test results would closely mirror conditions in orbit.

Using a data acquisition system sampling at 100,000 times per second, the team captured an exceptionally detailed view of the nut’s shock behaviour during actuation. Over multiple test cycles, the uD3RN was actuated in a controlled environment while high-speed sensors recorded every detail of the release event—from initial trigger to full separation. This comprehensive dataset enabled the construction of a precise Shock Response Spectrum (SRS) for each actuation.

Dcubed Performance

The results, documented in this paper, speak for themselves. Across all trials, the Dcubed uD3RN Micro Release Nut consistently delivered exceptionally low SRS levels no greater than 330 g over a bandwidth of 10 Hz – 10 kHz, confirming its status as one of the lowest-shock release mechanisms currently available. The shock output remained highly stable between triggers, demonstrating a level of reliability and repeatability critical for space missions.

Conclusion

Thanks to this independent validation, mission designers now have a proven, flight-ready and ultra-low shock solution for deploying critical hardware with minimal mechanical disturbance—reducing risk and expanding what’s possible in spacecraft design.